CASE STUDY

Industry: Manufacturing/Packaging

Product: Triton 5.0 MP Color Camera Feat. Sony IMX264

SDK: Custom Vision Software by PENSUR Using Halcon SDK

Efficient Vision Guided Pick & Place System for Blister Packaging

Blister packs are commonly used as unit-dose packaging for consumer goods or small tablets and capsules. The pre-formed plastic packaging has two primary components: a cavity made from either plastic or aluminum, and the lidding made from paper, plastic, aluminum or a lamination of soft foil and other substances. The cavity contains the product and the lidding seals the product in the package.

During filling, products are first fed properly to the preformed cavities, then lidding material gets sealed onto the support material. Even though every item may be identified and inspected prior to packaging, the risk of product damage or a mishap during the blister filling process remains and often requires manual interaction.

Challenge

Previously, the process of sorting and packaging products consisted of two stages. First, for each product line to be packaged, products had to be manually organized and placed into boxes for easier access at the next stage. After that, an operator would insert each product box into a blister molded by the machine. This type of manual labor makes operators prone to work related injuries by repetitive movement, as tens of thousands of products are blistered every day. Another challenge was to consider speed and accuracy requirements and to support various product lines with different sizes, shapes, and designs. A custom calibration procedure needed to be developed to achieve a low picking error of 0.5 mm.

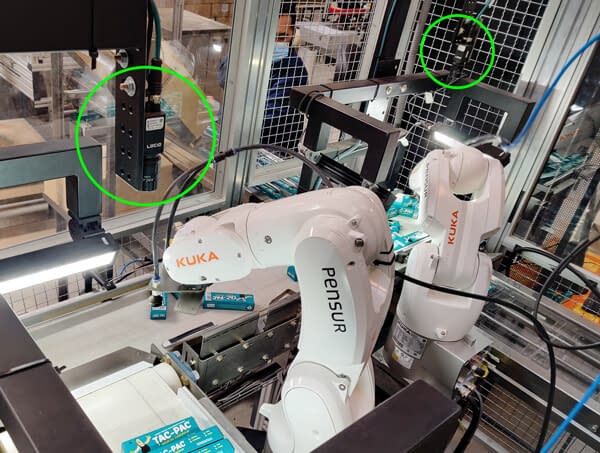

To reduce the need for intensive manual labor when sorting and placing boxes in the blisters, a more efficient vision-based pick and place solution was developed by Pensur, an engineering company who provides cutting edge automation solutions with industry grade components. Fast and reliable hardware, and optimized software customized made it possible for speed requirements to be met. Custom computer vision software combined with LUCID’s Triton cameras were used to train and identify each product accurately.

Check out the pick-and-place system in action! ———->

Solution

Each system includes two LUCID TRI050 color cameras used for the location and identification of the products which in this application were adhesive goods. The GigE Vision cameras are connected to separate Gigabit ports for maximum speed and triggered by their opto-isolated pins by the robots in order to synchronize with the picking system. “LUCID’s camera image quality combined with good optics allowed for precise and consistent identification of the products throughout the field of view”, says Pablo Senatore, Electrical Engineer and Project Manager at Pensur. The custom vision software was developed by Pensur using MVTec’s Halcon SDK.

The solution consists of a control panel, a processing unit, an elevator conveyor and a pair of robot-camera-conveyor systems. Firstly, the products to be blistered are selected at the control panel, where the operator can choose among more than 30 different products.

After that, the products are fed with the elevator conveyor, allowing a constant rate for the product sorting stage. These boxes arrive at the first robot’s workspace through a horizontal conveyor. Images are then captured with LUCID’s 5.0 MP Triton color camera featuring the Sony IMX264 global shutter CMOS image sensor. After being processed, the system decides which box to pick, and depending on how the product box should arrive at the blistering stage, it positions it accordingly on the second system’s conveyor belt. Lastly, as boxes arrive at the second robot’s workspace, the boxes are located, barcodes are verified, and with this information the robot either places the boxes in the blister or discards them.

The implemented solution merges both stages into one station. Products start on an elevator conveyor, where the first robot with the help of the Triton camera sorts the products. This sorting guarantees that the correct face of the product box arrives at the second robot for the camera to recognize. The second stage locates the boxes, verifies their identity with its barcode and places them on the blisters at a rate of 45 boxes per minute.

Conclusion

Traditional pick and place blister inspection systems have a complex teaching process for new products which frequently change in shape, size, position etc., and are often difficult for operators to use. By using fast and reliable hardware components and a custom-specific vision software, this state-of-the-art pick and place system brings cost savings and increases employee’s productivity and safety on the production floor by maximizing labor efficiency and a high throughput.

To learn more visit:

Pensur

Triton product page

Support Center

Support Center